AeroElectric Connection

|

Bob's Shop Notes: |

|

Bob's Shop Notes: |

| Click Here for Larger Image

|

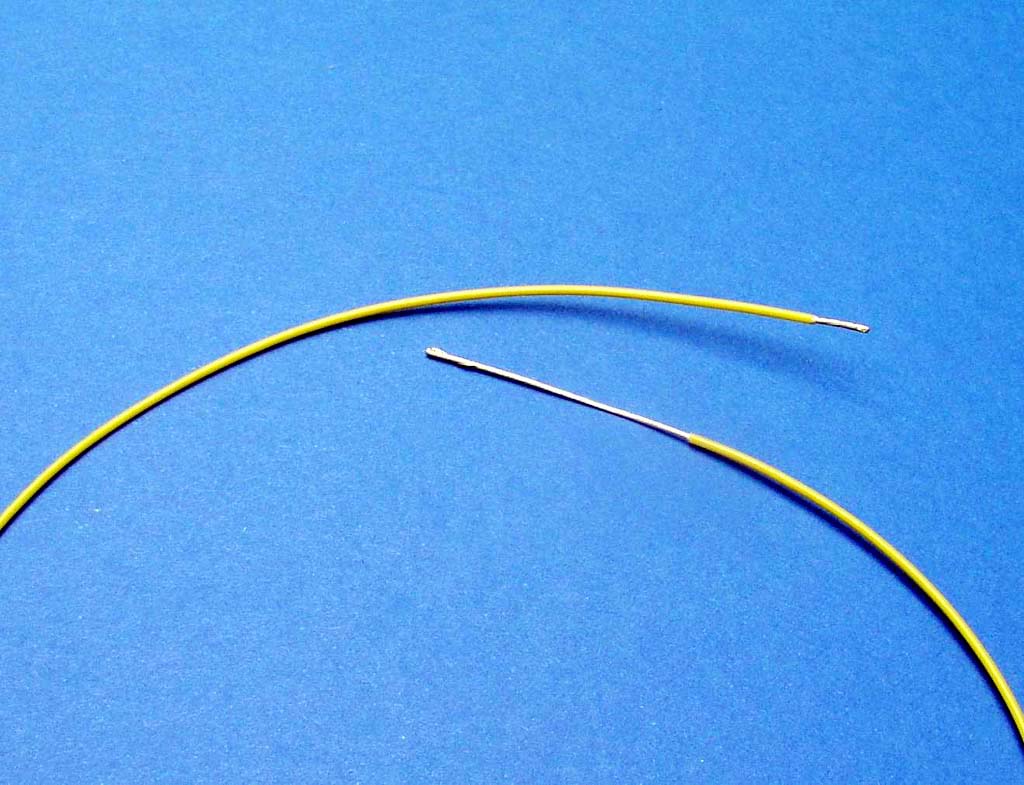

High quality permanent splices applied with crimp tools can add considerable

bulk to a multi-wire bundle. Modern crimp splices for aircraft are now available

with very small diameters and volumes . . . but the individual splices and

tools for installation are not cheap. Consider this technique which offers the

same integrity and space savings with a little more effort and a lot less cost. Begin by stripping wires to be joined approx 0.3" and 1.3" as shown: |

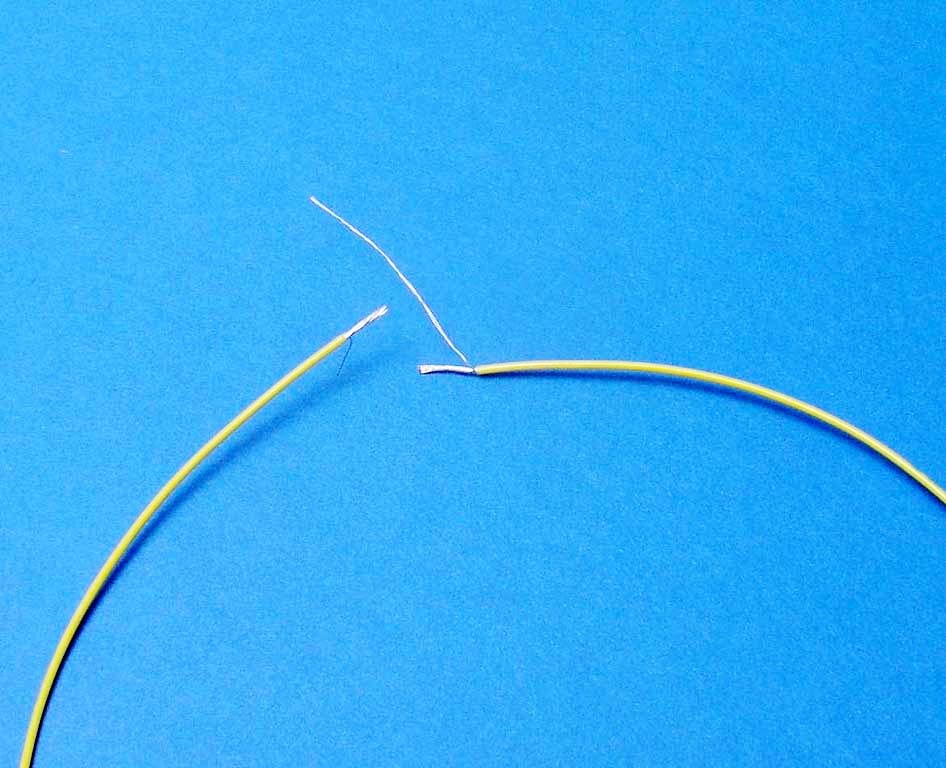

| Tease a strand of wire out of the layup on the long strip and cut remaining layup to 0.3" . . . | Click Here for Larger Image

|

| Click Here for Larger Image

|

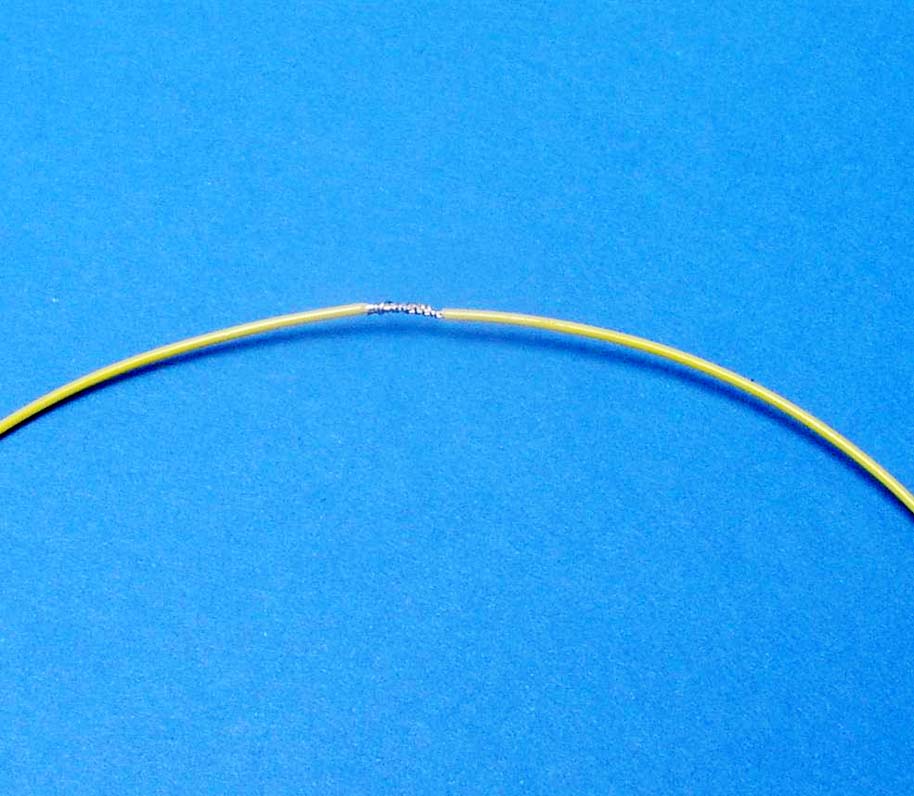

Now is the time to slip a piece of heatshrink over one of the wires.

Overlap exposed wires and wrap loose strand around the

joint to fixture the wires with respect to each other . . . Solder the joint with tools of choice . . . |

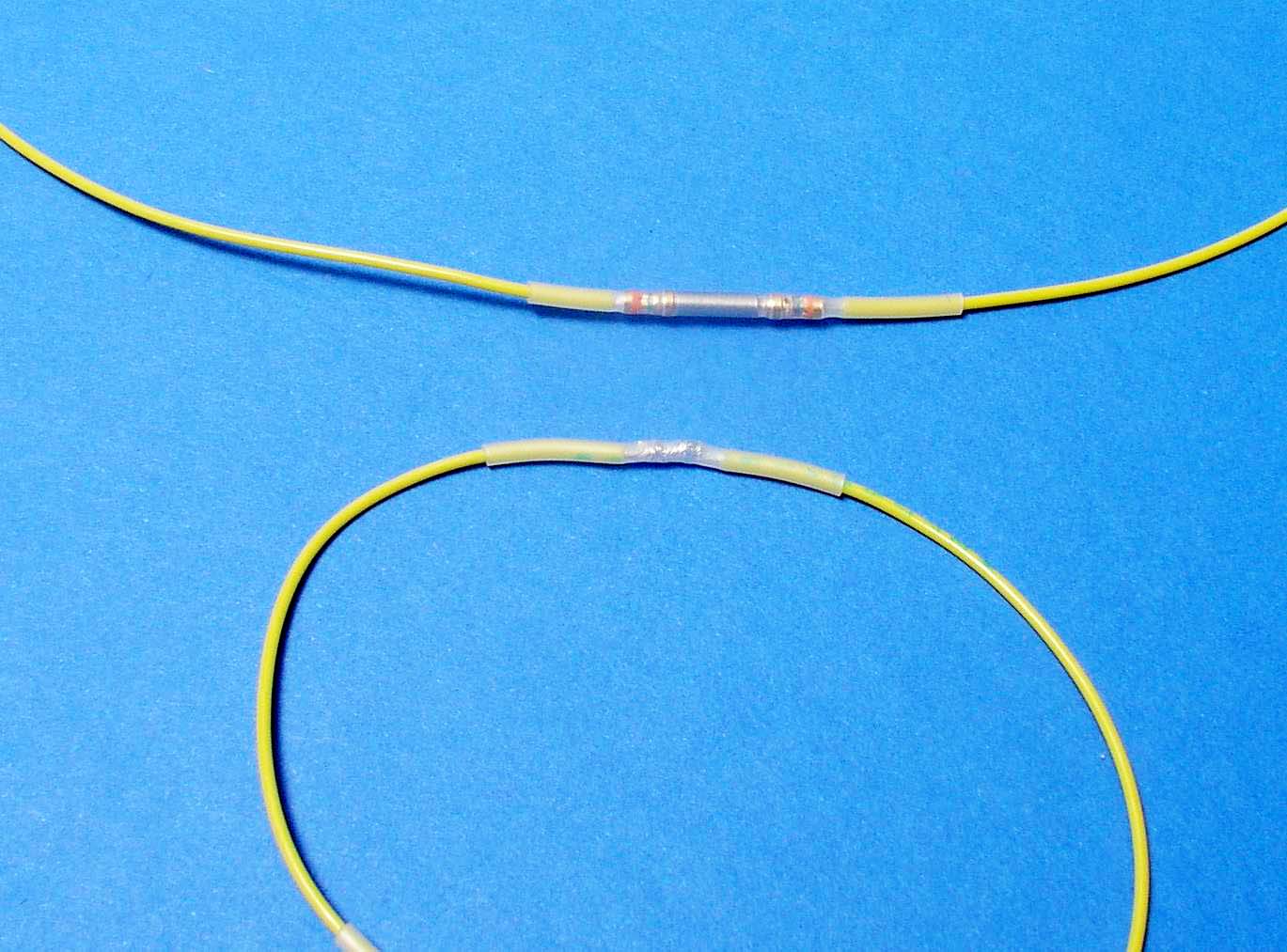

| Slip heatshrink over the soldered joint and apply heat to finish

the splice . . . Here's a lap-soldered joint next to a d-sub pins joint. If you anticipate a future need to open the joint for maintenance, D-sub pins under heat-shrink are an ideal substitute for the more classic knife splices in small wires. If the joint is permanent, may I suggest that the soldered lap joint is preferred and costs less. Of course, if soldering is inconvenient or not possible, D-sub pins under heatshrink is a perfectly acceptable addition to your bag of tricks for quality splicing of small wires. |

Click Here for Larger Image

|