|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Thu Jul 15, 2010 6:36 am Post subject: Facet Boost Pump Fuses Posted: Thu Jul 15, 2010 6:36 am Post subject: Facet Boost Pump Fuses |

|

|

Hi!

I'm wondering what size fuse to use for my Facet 40104 boost pump. I talked to somebody in their engineering department and he said 3 is recommended. I told him I'd heard of a couple people blowing 3A fuses in a 40105. They replaced it with a 5A and had no further problems. For some reason Facet is stingy with documentation. They list 20 or more pumps and give only their psi and gph ranges individually, then lump them all together and say they draw an average of 1.6A. The 04 I have is the smallest, with the 05 only slightly bigger. http://www.facet-purolator.com/index.php?option=com_content&task=category§ionid=7&id=16&Itemid=31

I asked if putting a 5A in would work. The Facet dude said it probably would work, but it'd increase the chance of wrecking the coil, but wouldn't get hot enough to start a fire. I have 15-20' round trip of 20awg wire going to it, so I know a 5A fuse would protect the wire. I plan on using this as a boost pump for my mechanical, turning it on before startup, check the pressure, then some seconds later crank the engine. It would then be turned off at altitude and back on for landing. The boost pump is near the bottom of the cowl, ~1' below the mechanical pump. They are in series with no recirculation, so it would be pumping with no flow until cranking.

The fuses I'm thinking of are the fast ATO/ATC style. I could go with slower 3AG fuses, if there is a any advantage in doing this. I assume that if the Facet is pumping against a closed valve a couple feet downstream it would in a few seconds reach its max current draw. I haven't heard of anyone wrecking their boost pump, just a few that blew 3A fuses.

I'm waiting for Facet to return my emailed questions. I also could bench test this pump with my VOM and see what the current draw really is.

Suggestions?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Dan |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Jul 15, 2010 1:40 pm Post subject: Facet Boost Pump Fuses Posted: Thu Jul 15, 2010 1:40 pm Post subject: Facet Boost Pump Fuses |

|

|

At 09:36 AM 7/15/2010, you wrote:

| Quote: |

Hi!

I asked if putting a 5A in would work. The Facet dude said it

probably would work, but it'd increase the chance of wrecking the

coil, but wouldn't get hot enough to start a fire.

|

That is . . . shall we say . . . no . . . I'll be civil.

First, supply fuse (at least in an airplane) is never

intended to protect devices . . . only wiring.

| Quote: | I have 15-20' round trip of 20awg wire going to it, so I know a 5A

fuse would protect the wire. I plan on using this as a boost pump

for my mechanical, turning it on before startup, check the

pressure, then some seconds later crank the engine. It would then be

turned off at altitude and back on for landing. The boost pump is

near the bottom of the cowl, ~1' below the mechanical pump. They are

in series with no recirculation, so it would be pumping with no flow

until cranking.

|

If it's 20AWG, put a 7A fuse in an don't loose

any sleep over it. Having too robust a feeder

protection cannot put anything inside the pump

at risk.

| Quote: | The fuses I'm thinking of are the fast ATO/ATC style. I could go

with slower 3AG fuses, if there is a any advantage in doing this. I

assume that if the Facet is pumping against a closed valve a couple

feet downstream it would in a few seconds reach its max current

draw. I haven't heard of anyone wrecking their boost pump, just a

few that blew 3A fuses.

I'm waiting for Facet to return my emailed questions. I also could

bench test this pump with my VOM and see what the current draw really is.

|

We had a thread on this topic some months ago. The

current draw by solenoid pumps is pulsed. I cited

a number of patents that go back to the 50s or earlier.

The first devices had mechanical contacts that pulsed

the coil when the fuel pumping piston approached end

of stroke thus pulling the piston back against a spring

for another stroke. The energy consumption of these

pumps WAS somewhat dependent in fuel flow. You could

hear the stroke-rate go up as flow increased.

Modern pumps are all solid state, no switches and

simply pulse the coil so many times per minute irrespective

of flow rate. If the flow is high, the piston strokes

long in the bore. If the flow is low, the piston barely

moves with each pulsed and tends to stay in the max

compressed end of the stroke.

Trying to get any sort of current measurement on

on of these things by watching a meter is meaningless.

It will be all over the place. A true ENERGY

measurement must be made with some RMS type ammeter

having a very long time constant . . . or a fast

data acquisition system that will secure a sufficiently

verbose data stream to do bit-wise integration of

current values.

I've got that on my list of things to do . . . in fact,

there's a Facet pump on my bench loaned to me by a

generous Lister for that purpose. I tried to get

real engineering data from Facet on several occasions

with no success. I'm doubtful that anyone there

even understood the question.

Nonetheless, the have been building a really slick,

trouble-free product for a very long time. You don't

have to know how it all works to serve great hamburgers,

fries and a shake . . . just follow directions. It's

the ISO way.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jloram

Joined: 07 Nov 2009

Posts: 54

Location: United States

|

Posted: Thu Jul 15, 2010 6:20 pm Post subject: Facet Boost Pump Fuses Posted: Thu Jul 15, 2010 6:20 pm Post subject: Facet Boost Pump Fuses |

|

|

[quote] --

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Fri Jul 16, 2010 10:57 am Post subject: Re: Facet Boost Pump Fuses Posted: Fri Jul 16, 2010 10:57 am Post subject: Re: Facet Boost Pump Fuses |

|

|

Thanks, Bob

Nice to get some background on how the pump works.

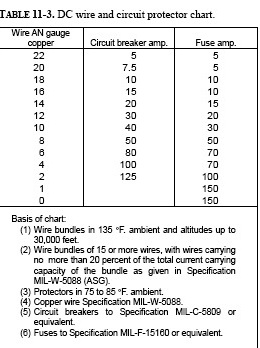

Facet told me in an email 5A would be fine, I see from Table 11-3 of AC43.13-1B a 5A fuse would work, and you say 7A is peachy. So I'm happy and will think no more about this issue.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

36.83 KB |

| Viewed: |

6295 Time(s) |

|

_________________

Dan |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Jul 16, 2010 5:05 pm Post subject: Facet Boost Pump Fuses Posted: Fri Jul 16, 2010 5:05 pm Post subject: Facet Boost Pump Fuses |

|

|

> If it's 20AWG, put a 7A fuse in an don't loose

> any sleep over it. Having too robust a feeder

> protection cannot put anything inside the pump

> at risk.

>

Would this reasoning not lead to running "really" robust feeders/fuses, and

then a fuel pump (or other device) with and internal problem that is

generating a lot of heat (fire/smoke)?

I agree that we're not trying to 'save/protect' the pump, rather trying to

prevent smoking wires, but a smoking load can be a big problem, too.

Most devices we use in our airplanes are considered

not flight worthy if they exhibit any failure mode that

becomes a hazard source for combustion . . . emitting

smoke is frowned upon too. The "really robust" feeders

was more rhetorical than anything else . . . after all,

with a fuse block, one has the option of selecting the

optimal fuse for each application . . . and easily

changing it if later circumstances suggest it's a

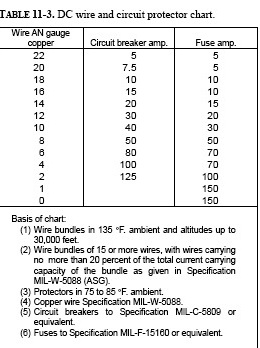

good idea. Specifically, with the FACET being a low

energy device totally enclosed in a metal box. The

risks are nil . . .

[img]cid:7.1.0.9.0.20100716195619.01fe8f38(at)aeroelectric.com.0[/img]

Although I seem to recall that G. Richter suggested

that the entire airplane could be configured with an

array of one-size-fits-all, self-resetting PTC polyswitches

soldered to a nifty etched circuit board product he

offered. But when it's so easy to achieve the elegant

solution, why not do it?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

26.77 KB |

| Viewed: |

6285 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|