|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

bvnj(at)yahoo.com

Guest

|

Posted: Wed Jul 06, 2011 8:46 am Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 8:46 am Post subject: why put baffle seals outside the baffle |

|

|

Gary and all,

A number of people suggest that if you put seals on the inside, the air pressure pushes them against the baffles and provides a better seal, while if you put them outside, the air will try to escape between the rivets.

So what are the reasons to put the baffle seals on the outside of the cylinder and rear baffles?

Thank you,

-Boris

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Wed Jul 06, 2011 11:28 am Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 11:28 am Post subject: why put baffle seals outside the baffle |

|

|

Boris,

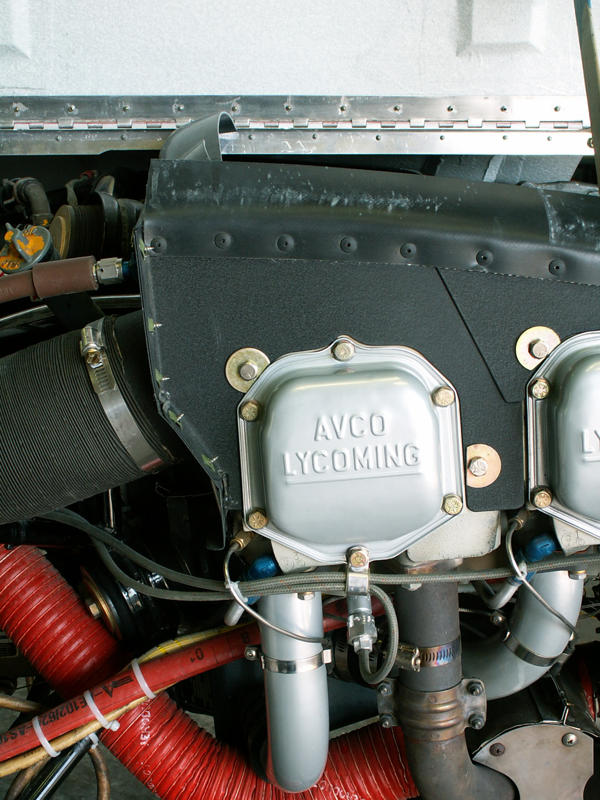

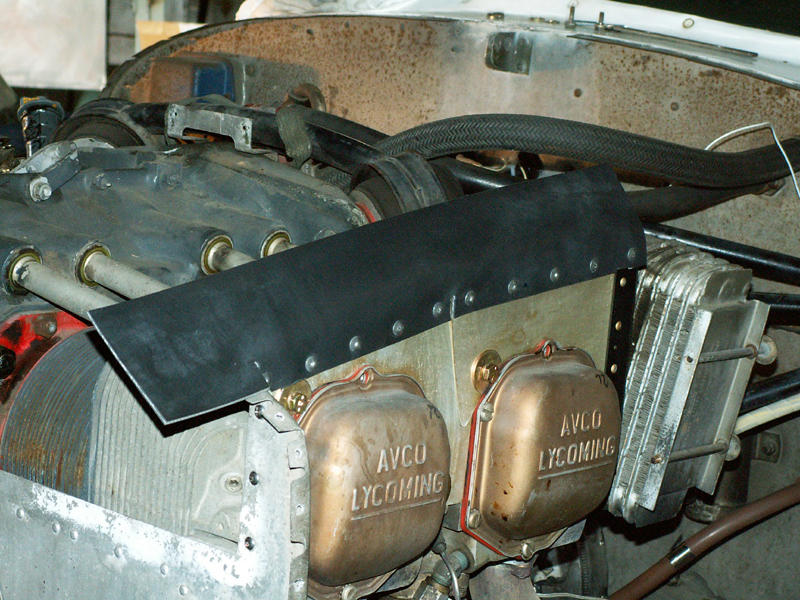

I've heard this argument before and it's total bullshit. The baffle seals bend over the baffle and seal between the baffle and the cowling. If you want baffle seals to conform to the shape of your cowling, follow the directions. Otherwise, you'll end up with baffles that stick straight up into the air and you'll never get the cowling closed.

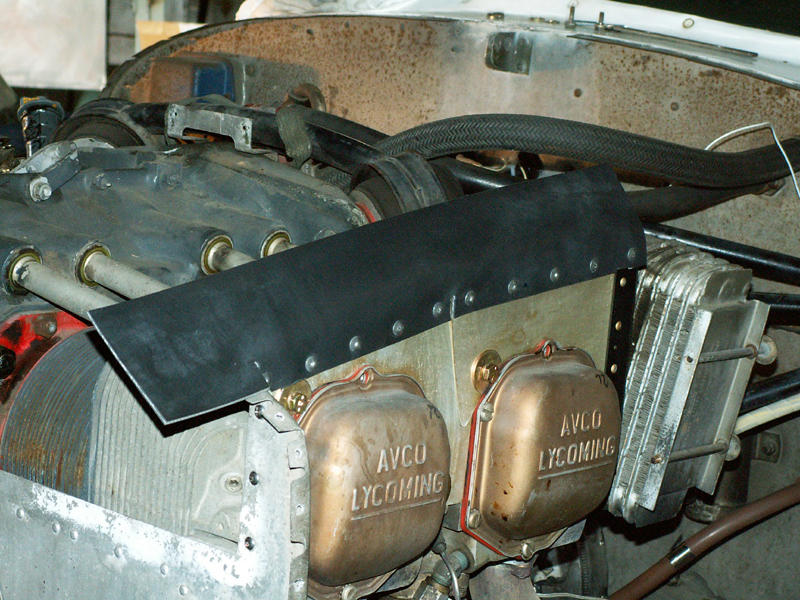

A very well known Grumman expert puts the seals on the inside and then bends the metal baffles to force the seal to bend over. This not only makes it nearly impossible to remove the plugs, but it looks like shit too.

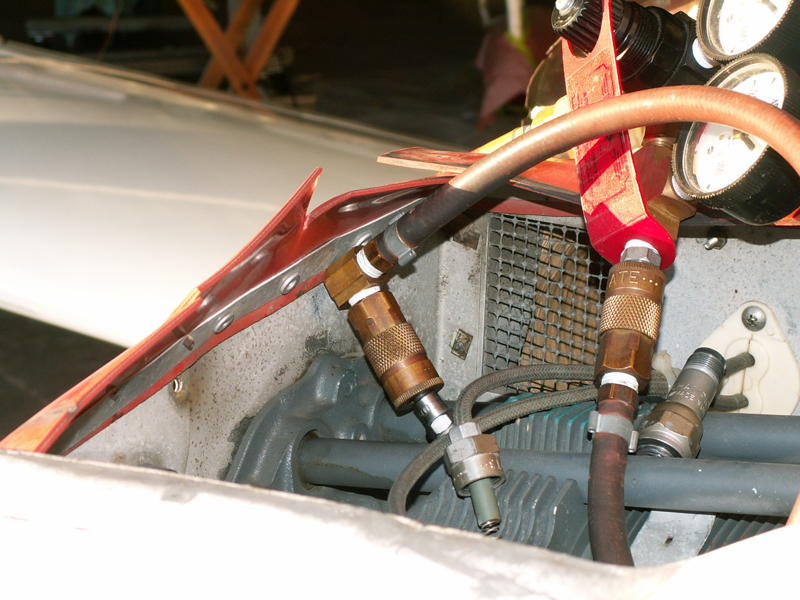

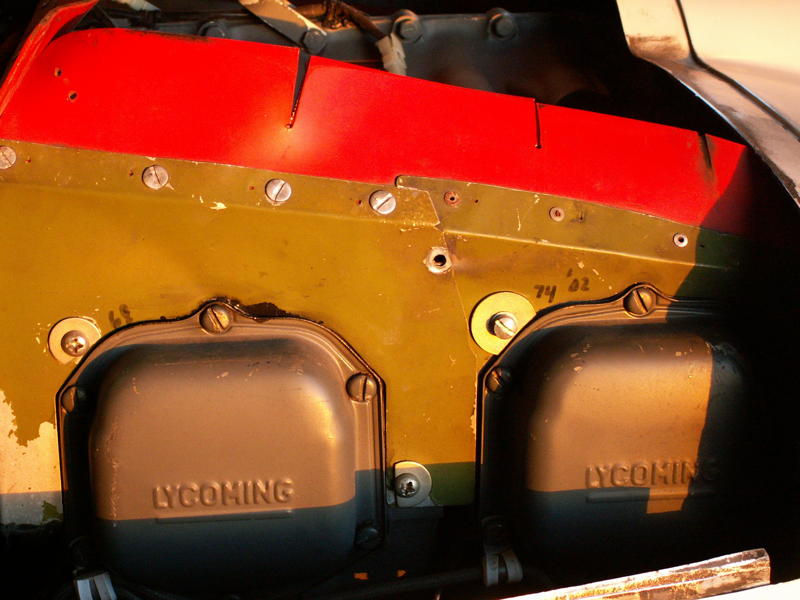

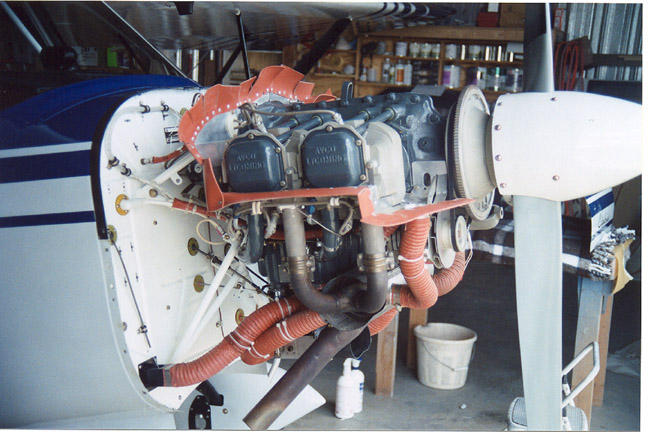

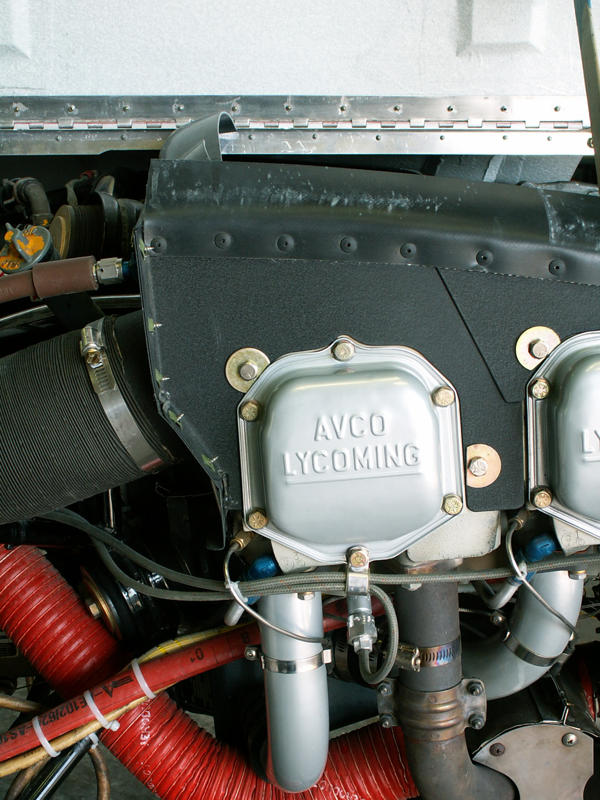

see pics.

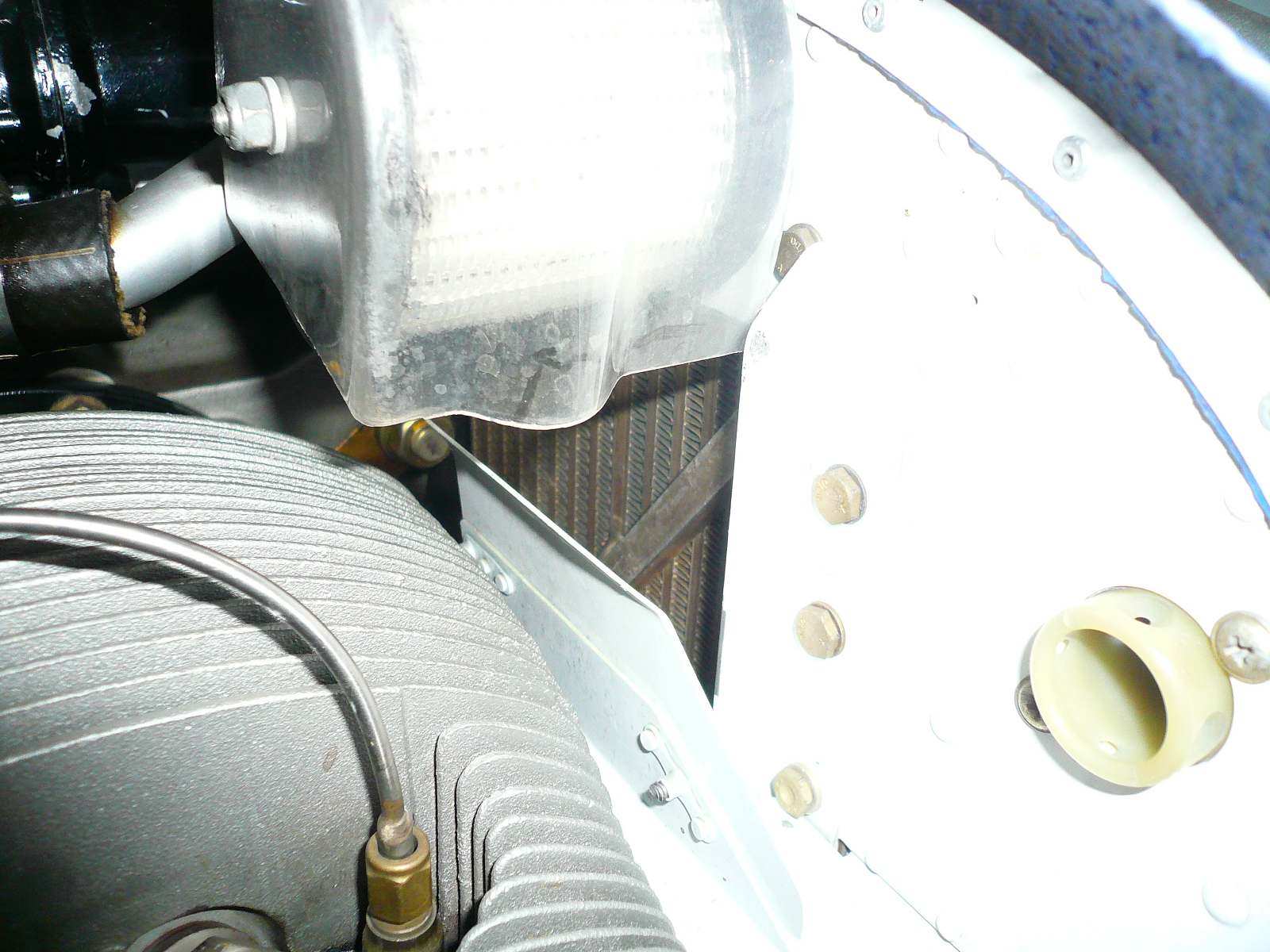

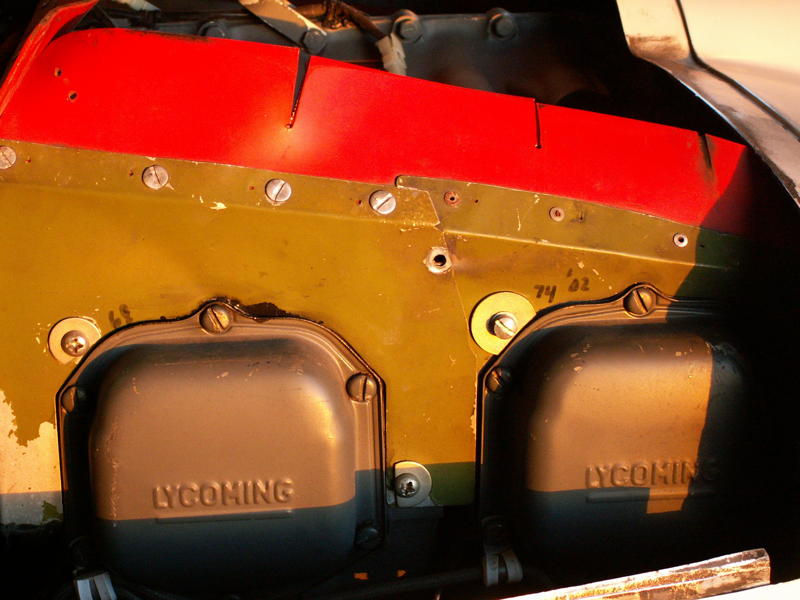

First set: customers plane. How not to do baffles.

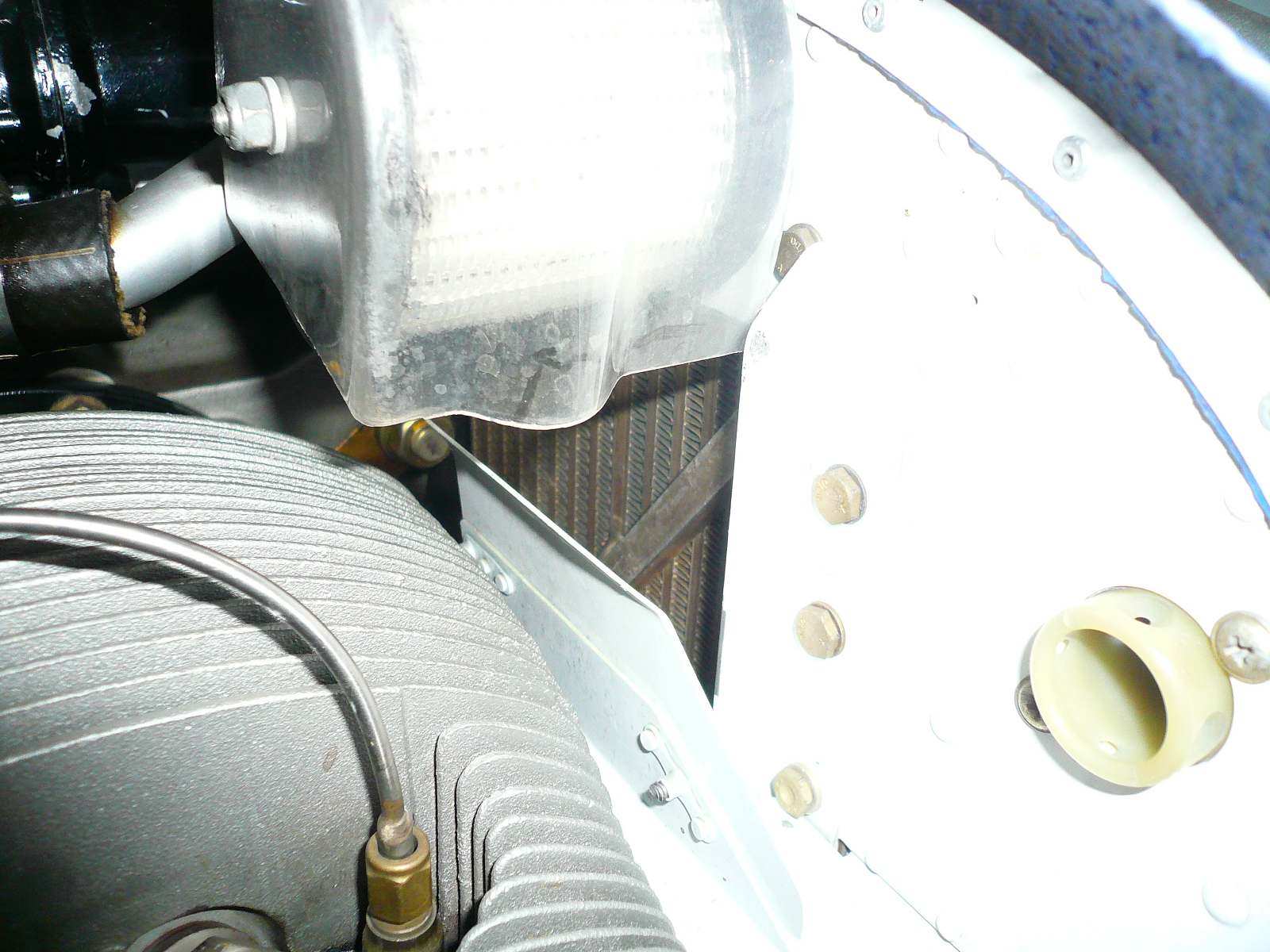

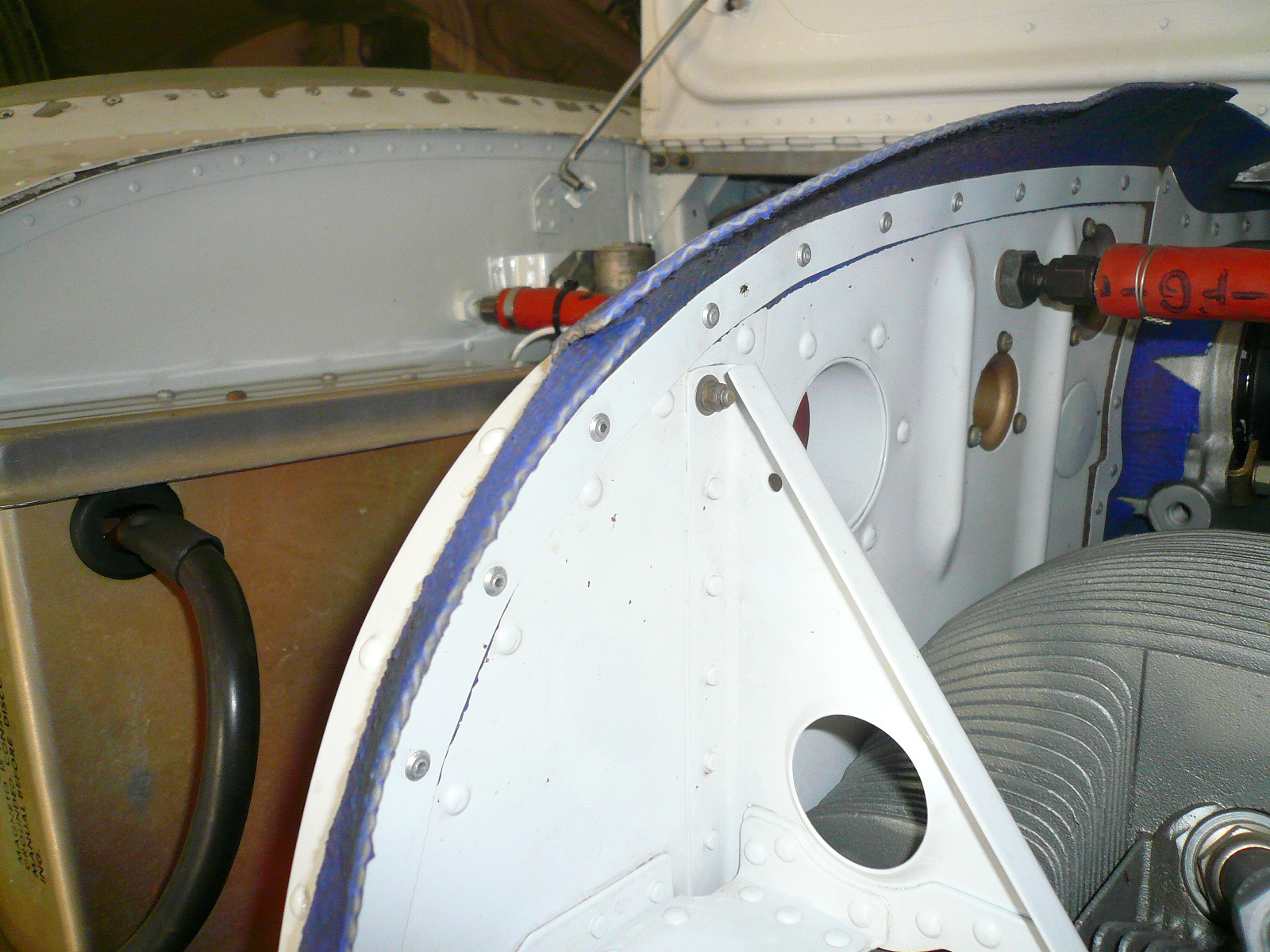

Second set: my plane. Note how the baffles conform to the shape of the cowling.

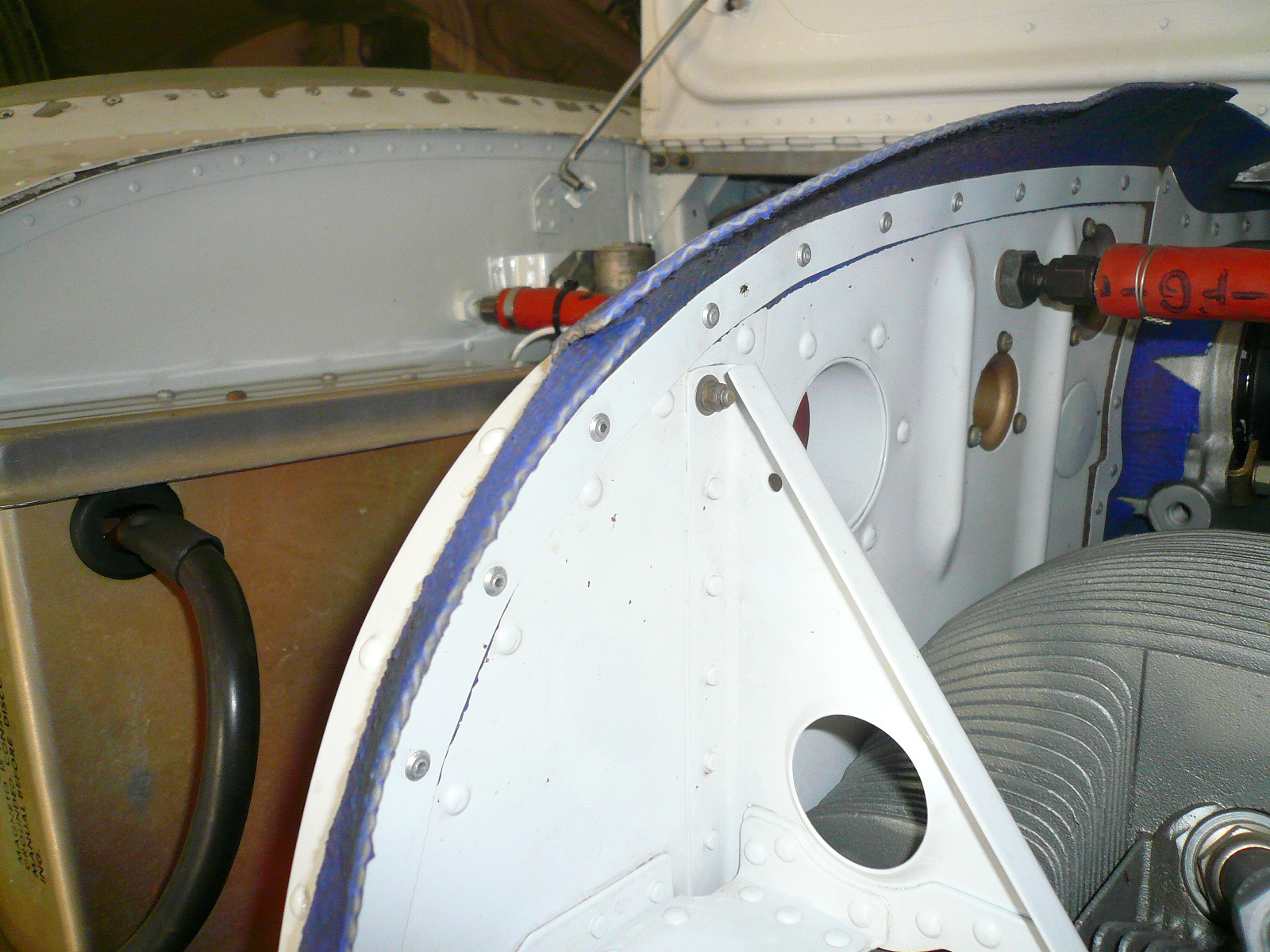

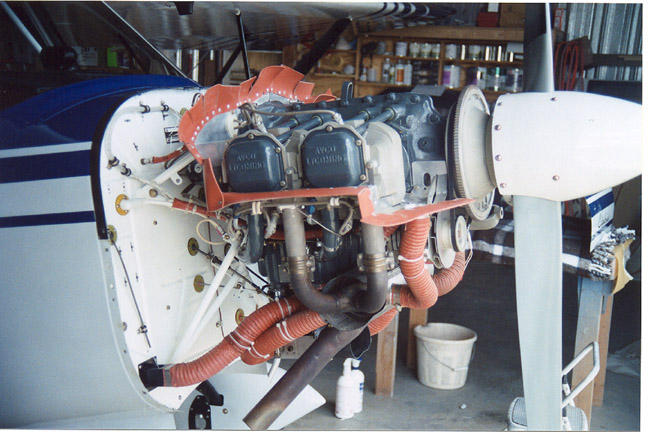

Third set: N119ST. This is during the installation of the baffles on N119ST. These are new baffle seals. Note how they conform to the shape of the cowling.

I would feel confident in saying that there are few mechanics, A&Ps, plane owners, or novices that know how to correctly install baffle seals so they fit properly.

Go to www.AuCountry.com and click on Restoration. Under 2003, you'll see Baffle Installation. That may help.

Gary

PS. Now ask how I really feel about baffles/baffle seals. {smile}

From: b v <bvnj(at)yahoo.com>

To: Teamgrumman <teamgrumman-list(at)matronics.com>

Sent: Wed, July 6, 2011 9:43:31 AM

Subject: why put baffle seals outside the baffle

--> TeamGrumman-List message posted by: b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)>

Gary and all,

A number of people suggest that if you put seals on the inside, the air pressure pushes them against the baffles and provides a better seal, while if you put them outside, the air will try to escape between the rivets.

So what are the reasons to put the baffle seals on the outside of the cylinder and rear baffles?

Thank

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

65.86 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

66.91 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

60.51 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

62.04 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

58 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

61.2 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

100.18 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

102.86 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

92.75 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

83.22 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

83.32 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

70.39 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

66.49 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

72.18 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

62.85 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

53.89 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

62.8 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

65.05 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

62.23 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

67.78 KB |

| Viewed: |

3970 Time(s) |

|

| Description: |

|

| Filesize: |

60.71 KB |

| Viewed: |

3970 Time(s) |

|

|

|

| Back to top |

|

|

pitts_pilot(at)bellsouth.

Guest

|

Posted: Wed Jul 06, 2011 12:17 pm Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 12:17 pm Post subject: why put baffle seals outside the baffle |

|

|

On 7/6/2011 3:25 PM, Gary Vogt wrote: | Quote: | Boris,

I've heard this argument before and it's total bullshit. The baffle seals bend over the baffle and seal between the baffle and the cowling. If you want baffle seals to conform to the shape of your cowling, follow the directions. Otherwise, you'll end up with baffles that stick straight up into the air and you'll never get the cowling closed.

A very well known Grumman expert puts the seals on the inside and then bends the metal baffles to force the seal to bend over. This not only makes it nearly impossible to remove the plugs, but it looks like shit too.

|

snip

Good pics Gary! I've seen quite a few really bad cowl seal installations .... admittedly on homebuilts.

Almost every baffle segment is attached to a curved edge. I attach the baffle seal material using the 'devide and conquer' method. I attach the material to the outside at the mid-point of the curve. I use the outside because so the seal material protects the cowl from the aluminum edge .... if it's close and the engine rocks. The next rivet 1/2 way to one end, pulling it down just a little so it folds over towards the inside. Do the other side 1/2 way towards the end. Continue the stretching/riveting until you're satisfied. Once all the riveting is done I run a small bead of silicone along the top of the aluminum edge and lay the top cowl on until the silicone cures. I've had the best luck this way.

Now, as for the material. I use the thin fiberglass reinforced stuff like in Gary's pictures. I've seen a lot of 1/8" silicone installations and they all look like crap. The thin stuff forms much easier to the cowl shape and is easier to work that subtle curve.

Linn

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Wed Jul 06, 2011 12:55 pm Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 12:55 pm Post subject: why put baffle seals outside the baffle |

|

|

I start at one end at 3/4 inches overlap. The first two rivets are quite close together . . . 1 inch or less. The next ones are installed at intervals needed to form the curve.

From: Linn Walters <pitts_pilot(at)bellsouth.net>

To: teamgrumman-list(at)matronics.com

Sent: Wed, July 6, 2011 1:14:11 PM

Subject: Re: why put baffle seals outside the baffle

On 7/6/2011 3:25 PM, Gary Vogt wrote: | Quote: | Boris,

I've heard this argument before and it's total bullshit. The baffle seals bend over the baffle and seal between the baffle and the cowling. If you want baffle seals to conform to the shape of your cowling, follow the directions. Otherwise, you'll end up with baffles that stick straight up into the air and you'll never get the cowling closed.

A very well known Grumman expert puts the seals on the inside and then bends the metal baffles to force the seal to bend over. This not only makes it nearly impossible to remove the plugs, but it looks like shit too.

|

snip

Good pics Gary! I've seen quite a few really bad cowl seal installations .... admittedly on homebuilts.

Almost every baffle segment is attached to a curved edge. I attach the baffle seal material using the 'devide and conquer' method. I attach the material to the outside at the mid-point of the curve. I use the outside because so the seal material protects the cowl from the aluminum edge .... if it's close and the engine rocks. The next rivet 1/2 way to one end, pulling it down just a little so it folds over towards the inside. Do the other side 1/2 way towards the end. Continue the stretching/riveting until you're satisfied. Once all the riveting is done I run a small bead of silicone along the top of the aluminum edge and lay the top cowl on until the silicone cures. I've had the best luck this way.

Now, as for the material. I use the thin fiberglass reinforced stuff like in Gary's pictures. I've seen a lot of 1/8" silicone installations and they all look like crap. The thin stuff forms much easier to the cowl shape and is easier to work that subtle curve.

Linn

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

bvnj(at)yahoo.com

Guest

|

Posted: Wed Jul 06, 2011 1:00 pm Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 1:00 pm Post subject: why put baffle seals outside the baffle |

|

|

Thank you for the pictures, Gary!

I have just learned so much! For example, I need to make a cut-out in the cabin heat inlet duct to accommodate the alternator belt adjustment bolt.

Another "Other people suggest" question - this one about baffle seal material. I heard people say that the reinforced baffle seals wear out and expose the reinforcement material and it starts rubbing holes in the top cowl and for that reason they prefer non-reinforced silicone seals. I haven't seen it rub a hole all the way thru, but I have seen some damage in the top aluminum cowl. Some people suggest to put aluminum tape to cover the contact area as a remedy. What do you think?

Your plane has a standard exhaust! How come?

The N119ST baffle doesn't have a cut-out for the hinge. Are you using a one-piece top cowl now?

Thank you,

-Boris

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Wed Jul 06, 2011 1:07 pm Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 1:07 pm Post subject: why put baffle seals outside the baffle |

|

|

Boris:

You will see ware on the cowl after a while. My cure is to use 100 MPH aluminum tape and line out the area where the seal contacts the cowl.

Looks good, easy to clean and prevents ware... AND easy to replace.

I have some so after you paint call me.

Barry

On Wed, Jul 6, 2011 at 4:58 PM, b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)> wrote:

[quote]--> TeamGrumman-List message posted by: b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)>

Thank you for the pictures, Gary!

I have just learned so much! For example, I need to make a cut-out in the cabin heat inlet duct to accommodate the alternator belt adjustment bolt.

Another "Other people suggest" question - this one about baffle seal material. I heard people say that the reinforced baffle seals wear out and expose the reinforcement material and it starts rubbing holes in the top cowl and for that reason they prefer non-reinforced silicone seals. I haven't seen it rub a hole all the way thru, but I have seen some damage in the top aluminum cowl. Some people suggest to put aluminum tape to cover the contact area as a remedy. What do you think?

Your plane has a standard exhaust! How come?

The N119ST baffle doesn't have a cut-out for the hinge. Are you using a one-piece top cowl now?

Thank you,

-Boris

===========

List" target="_blank">http://www.matronics.com/Navigator?TeamGrumman-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

[b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Discover

Joined: 26 Feb 2007

Posts: 429

|

Posted: Wed Jul 06, 2011 1:38 pm Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 1:38 pm Post subject: why put baffle seals outside the baffle |

|

|

I use clear silicone on the upper cowl where the wear marks are. I put clear packing tape on the baffle seals and close the cowl and leave it over night. The next day I open the cowl, (the tape acts as a good releasing agent) peal the tape of the baffles and am done. The clear silicone spreads out nice and thin and doesn't change the appearance much like aluminum tape does. You can do this to seal around where the upper cowl doors contact the firewall and nosebowl....

One of the things I do is to use a shop light when its dark. I put the light behind the engine and close the cowl. The light helps to show all the leaks. I usually have to take a razor blade and split the baffles where they have folded away from the cowl, splitting it there will make it lay flat on the cowl. Sometimes I have used the above silicone method in reverse were I put a matching color silicone on on the baffle and the tape on the cowl.

When you close the cowl doors the shape of the seals changes. Look thru the air intakes during daylight to get an idea of how much the baffles need worked on.

Another area: There is usually a big gaping leak at the back cylinders down where the sun don't shine around the cylinder bolt nut. Gary's baffles are much better here than the factory but you can still seal it with silicone there.

[quote] ---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Wed Jul 06, 2011 2:55 pm Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 2:55 pm Post subject: why put baffle seals outside the baffle |

|

|

I use the 3/16 inch reinforced material from Bee-Gee. I buy it in 100 foot rolls from Sacramento Sky Ranch. You can probably buy it direct. You'll need about 4 feet or more.

The pics of my plane are pre-2005. Originally I was going to do both exhaust systems. Then I learned the cost of extra drawings and testing. Based on the number of cowling sales, I'll break even at about 50 to 60 cowlings. Had I done the stock exhaust system, figure another 30 cowlings.

I don't have any pics of my upper cowling and the wear on the baffle seals. For the most part, the Imron on the underside of the cowling will be smooth enough to stop chafing. There is some wear. But, after 7 years on my plane, nothing is worn through.

N119ST. It wasn't finished yet.

From: b v <bvnj(at)yahoo.com>

To: Teamgrumman <teamgrumman-list(at)matronics.com>

Sent: Wed, July 6, 2011 1:58:02 PM

Subject: Re: why put baffle seals outside the baffle

--> TeamGrumman-List message posted by: b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)>

Thank you for the pictures, Gary!

I have just learned so much! For example, I need to make a cut-out in the cabin heat inlet duct to accommodate the alternator belt adjustment bolt.

Another "Other people suggest" question - this one about baffle seal material. I heard people say that the reinforced baffle seals wear out and expose the reinforcement material and it starts rubbing holes in the top cowl and for that reason they prefer non-reinforced silicone seals. I haven't seen it rub a hole all the way thru, but I have seen some damage in the top aluminum cowl. Some people suggest to put aluminum tape to cover the contact area as a remedy. What do you think?

Your plane has a standard exhaust! How come?

The N119ST baffle doesn't have a cut-out for the hinge. Are you using a

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Wed Jul 06, 2011 7:35 pm Post subject: why put baffle seals outside the baffle Posted: Wed Jul 06, 2011 7:35 pm Post subject: why put baffle seals outside the baffle |

|

|

Barry,

I would challenge any installation you could do with what I do regarding longevity, sealing ability, and looks compared to mine. Inside is just not right.

From: FLYaDIVE <flyadive(at)gmail.com>

To: teamgrumman-list(at)matronics.com

Sent: Wed, July 6, 2011 6:44:29 PM

Subject: Re: why put baffle seals outside the baffle

Boris, Gary & Team:

Here are my thoughts on In Vs Out:

- There is no advantage of putting the silicon baffle material on the outside. Only a disadvantage.

- Why? Well if you think about it there is only 0.025 to 0.035" difference in position between inside and out. The thickness of the metal baffle.

- The difference is in which direction the NATURAL ROLL of the silicon goes. YOU MUST place the curve of the silicon baffle material to the INSIDE. This is true for BOTH the LENGTH and the WIDTH of the silicon baffle material.

- THERE IS A CURVE! ! !

- It's ugly! But beauty is in the eye of the beholder.

- Reinforced Vs Un-Reinforced:

- The Un-Reinforced is softer and will bend easier and conform easier.

- The Un-Reinforced will also deform easier when the Pop-Rivets are squeezed down. This causes and adds to the scalloping of the silicon baffle material.

- The Un-Reinforced will tear easier.

- The Cure for problems in #2 above:

- I use 1/8" thick x 1/2" wide x Required LONG LENGTHS of aluminum strips that function as a CONTINUOUS WASHER to hold down the silicon baffle material against the aluminum baffle material.

- This FLATTENS the silicon baffle material ELIMINATING ALL scalloping as well as stiffening the aluminium baffle material.

- So NOW you can use the softer, more flexible Non-Reinforced silicon baffle material. Which will give you a better seal and less ware.

- So, why on the inside if you do all the above? It LQQKs a hell of a lot better.

- Yes, you can still use the LONG LENGTHS of aluminum strips that function as a CONTINUOUS WASHER to hold down the silicon baffle material against the aluminum baffle material - On The Out Side.

- Oh! I use 5/8" Dia HEAD x 1/8" Dia Shank x 1/2" Long Shank - Pop-Rivets.

- To prevent tearing I stitch the over laps in the corners and 'V' cuts with dental floss.

Barry

On Wed, Jul 6, 2011 at 12:43 PM, b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)> wrote:

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

flyv35b(at)minetfiber.com

Guest

|

Posted: Thu Jul 07, 2011 7:51 am Post subject: why put baffle seals outside the baffle Posted: Thu Jul 07, 2011 7:51 am Post subject: why put baffle seals outside the baffle |

|

|

I believe that a good installation can be done either way. I've seen

baffles that were installed incorrectly from the back side that were cut

by the sharp edge of the metal baffle, probably because there wasn't

enough clearance between it and the cowling.

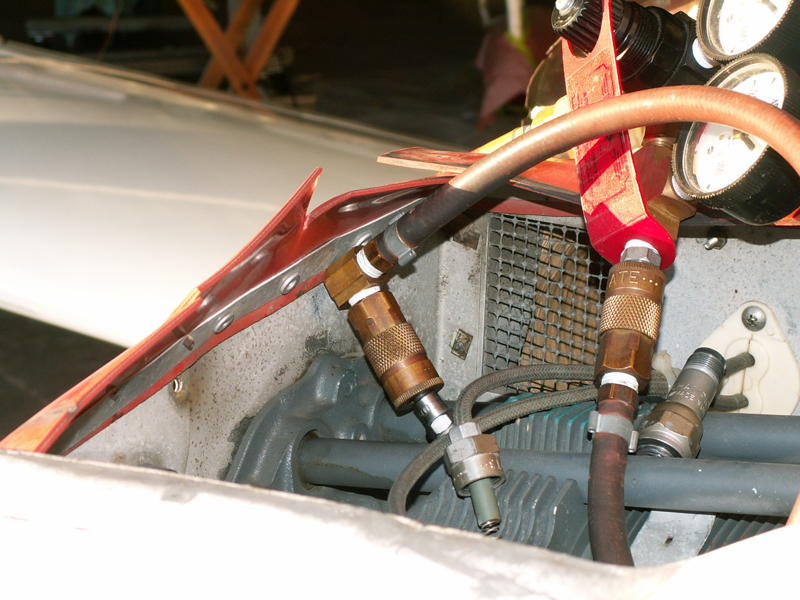

Here are 3 photos of what is a totally different arrangement than what

has been discussed, albeit not on a Grumman. Note that in the photo

(P1060256) of the front side that a top metal strip is riveted to a

flange and it sandwiches the seal material, forcing it to bend forward

and form a nice curvature.

The last photo (P106057) shows the oil cooler installation on the

opposite, LH side where the cooler is set back about 1.5 inches behind

the cylinder fins for improved air entrance flow. I think the Tiger

cooler could benefit from this sort of thing, although it wouldn't need

to be set back nearly as far.

Cliff

On 7/6/2011 8:33 PM, Gary Vogt wrote:

| Quote: | Barry,

I would challenge any installation you could do with what I do regarding

longevity, sealing ability, and looks compared to mine. Inside is just

not right.

------------------------------------------------------------------------

*From:* FLYaDIVE <flyadive(at)gmail.com>

*To:* teamgrumman-list(at)matronics.com

*Sent:* Wed, July 6, 2011 6:44:29 PM

*Subject:* Re: why put baffle seals outside the baffle

Boris, Gary & Team:

Here are my thoughts on In Vs Out:

1. There is no advantage of putting the silicon baffle material on

the outside. Only a disadvantage.

* Why? Well if you think about it there is only 0.025 to

0.035" difference in position between inside and out. The

thickness of the metal baffle.

* The difference is in which direction the NATURAL ROLL of the

silicon goes. YOU MUST place the curve of the silicon baffle

material to the INSIDE. This is true for BOTH the LENGTH and

the WIDTH of the silicon baffle material.

* THERE IS A CURVE! ! !

* It's ugly! But beauty is in the eye of the beholder.

2. Reinforced Vs Un-Reinforced:

* The Un-Reinforced is softer and will bend easier and conform

easier.

* The Un-Reinforced will also deform easier when the

Pop-Rivets are squeezed down. This causes and adds to the

scalloping of the silicon baffle material.

* The Un-Reinforced will tear easier.

3. The Cure for problems in #2 above:

* I use 1/8" thick x 1/2" wide x Required LONG LENGTHS of

aluminum strips that function as a CONTINUOUS WASHER to hold

down the silicon baffle material against the aluminum baffle

material.

* This FLATTENS the silicon baffle material ELIMINATING ALL

scalloping as well as stiffening the aluminium baffle material.

* So NOW you can use the softer, more flexible Non-Reinforced

silicon baffle material. Which will give you a better seal

and less ware.

* So, why on the inside if you do all the above? It LQQKs a

hell of a lot better.

* Yes, you can still use the LONG LENGTHS of aluminum strips

that function as a CONTINUOUS WASHER to hold down the

silicon baffle material against the aluminum baffle material

- On The Out Side.

* Oh! I use 5/8" Dia HEAD x 1/8" Dia Shank x 1/2" Long Shank -

Pop-Rivets.

* To prevent tearing I stitch the over laps in the corners and

'V' cuts with dental floss.

Barry

On Wed, Jul 6, 2011 at 12:43 PM, b v <bvnj(at)yahoo.com

<mailto:bvnj(at)yahoo.com>> wrote:

<mailto:bvnj(at)yahoo.com>>

Gary and all,

A number of people suggest that if you put seals on the inside, the

air pressure pushes them against the baffles and provides a better

seal, while if you put them outside, the air will try to escape

between the rivets.

So what are the reasons to put the baffle seals on the outside of

the cylinder and rear baffles?

Thank you,

-Boris

===========

List"

target="_blank">http://www.matronics.com/Navigator?TeamGrumman-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

*

*

*

*

|

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

926.36 KB |

| Viewed: |

3946 Time(s) |

|

| Description: |

|

| Filesize: |

851.53 KB |

| Viewed: |

3946 Time(s) |

|

| Description: |

|

| Filesize: |

835.22 KB |

| Viewed: |

3946 Time(s) |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Thu Jul 07, 2011 11:28 am Post subject: why put baffle seals outside the baffle Posted: Thu Jul 07, 2011 11:28 am Post subject: why put baffle seals outside the baffle |

|

|

I did my Citabria, which has baffles that are not that different from those on a Bonanza, using my technique. I used 1/4 as much hardware and accomplished the same thing. The Citabria had baffle seals mounted on the inside. I copied them. By the time I was done, I wished I'd done them differently. Still, it worked OK.

I've included a few pics.

• The first one is a customer I did a few years ago. This is how the baffle lays over without any help.

•The next several pics are of an installation where the metal baffle was deformed to make the baffles fit. It's a brute force method that is really ugly and makes maintenance difficult.

•The next two are of my Citabria.

•The last one is of an installation of a LoPresti nosebowl. Notice the gap in the corner. There is no way to elegantly fill this gap. Unless the installer knows what he's doing, CHTs will be higher after installing a LoPresti nosebowl.

From: flyv35b <flyv35b(at)minetfiber.com>

To: teamgrumman-list(at)matronics.com

Sent: Thu, July 7, 2011 8:47:35 AM

Subject: Re: TeamGrumman-List: why put baffle seals outside the baffle

I believe that a good installation can be done either way. I've seen

baffles that were installed incorrectly from the back side that were cut

by the sharp edge of the metal baffle, probably because there wasn't

enough clearance between it and the cowling.

Here are 3 photos of what is a totally different arrangement than what

has been discussed, albeit not on a Grumman. Note that in the photo

(P1060256) of the front side that a top metal strip is riveted to a

flange and it sandwiches the seal material, forcing it to bend forward

and form a nice curvature.

The last photo (P106057) shows the oil cooler installation on the

opposite, LH side where the cooler is set back about 1.5 inches behind

the cylinder fins for improved air entrance flow. I think the Tiger

cooler could benefit from this sort of thing, although it wouldn't need

to be set back nearly as far.

Cliff

On 7/6/2011 8:33 PM, Gary Vogt wrote:

| Quote: | Barry,

I would challenge any installation you could do with what I do regarding

longevity, sealing ability, and looks compared to mine. Inside is just

not right.

------------------------------------------------------------------------

*From:* FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)>

*To:* teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

*Sent:* Wed, July 6, 2011 6:44:29 PM

*Subject:* Re: why put baffle seals outside the baffle

Boris, Gary & Team:

Here are my thoughts on In Vs Out:

1. There is no advantage of putting the silicon baffle material on

the outside. Only a disadvantage.

* Why? Well if you think about it there is only 0.025 to

0.035" difference in position between inside and out. The

thickness of the metal baffle.

* The difference is in which direction the NATURAL ROLL of the

silicon goes. YOU MUST place the curve of the silicon baffle

material to the INSIDE. This is true for BOTH the LENGTH and

the WIDTH of the silicon baffle material.

* THERE IS A CURVE! ! !

* It's ugly! But beauty is in the eye of the beholder.

2. Reinforced Vs Un-Reinforced:

* The Un-Reinforced is softer and will bend easier and conform

easier.

* The Un-Reinforced will also deform easier when the

Pop-Rivets are squeezed down. This causes and adds to the

scalloping of the silicon baffle material.

* The Un-Reinforced will tear easier.

3. The Cure for problems in #2 above:

* I use 1/8" thick x 1/2" wide x Required LONG LENGTHS of

aluminum strips that function as a CONTINUOUS WASHER to hold

down the silicon baffle material against the aluminum baffle

material.

* This FLATTENS the silicon baffle material ELIMINATING ALL

scalloping as well as stiffening the aluminium baffle material.

* So NOW you can use the softer, more flexible Non-Reinforced

silicon baffle material. Which will give you a better seal

and less ware.

* So, why on the inside if you do all the above? It LQQKs a

hell of a lot better.

* Yes, you can still use the LONG LENGTHS of aluminum strips

that function as a CONTINUOUS WASHER to hold down the

silicon baffle material against the aluminum baffle material

- On The Out Side.

* Oh! I use 5/8" Dia HEAD x 1/8" Dia Shank x 1/2" Long Shank -

Pop-Rivets.

* To prevent tearing I stitch the over laps in the corners and

'V' cuts with dental floss.

Barry

On Wed, Jul 6, 2011 at 12:43 PM, b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)

<mailto:bvnj(at)yahoo.com (bvnj(at)yahoo.com)>> wrote:

--> TeamGrumman-List message posted by: b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)

<mailto:bvnj(at)yahoo.com (bvnj(at)yahoo.com)>>

Gary and all,

A number of people suggest that if you put seals on the inside, the

air pressure pushes them against the baffles and provides a better

seal, while if you put them outside, the air will try to escape

between the rivets.

So what are the reasons to put the baffle seals on the outside of

the cylinder and rear baffles?

Thank you,

-Boris

===========

List"

target="_blank">http://www.matronics.com/Navigator?TeamGrumman-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

*

*

*

*

|

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

108.58 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

66.93 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

65.23 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

73.9 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

68.51 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

60.46 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

59.17 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

52.1 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

57.85 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

64.54 KB |

| Viewed: |

3941 Time(s) |

|

| Description: |

|

| Filesize: |

39.09 KB |

| Viewed: |

3941 Time(s) |

|

|

|

| Back to top |

|

|

michael(at)flightsked.com

Guest

|

Posted: Thu Jul 07, 2011 12:34 pm Post subject: why put baffle seals outside the baffle Posted: Thu Jul 07, 2011 12:34 pm Post subject: why put baffle seals outside the baffle |

|

|

Hmmm... I believe that I recognize that engine compartment.

Gary replaced my baffles, with new metal parts, and flexible material as he describes. It is definitely easier to access the plugs now - you can see on the old baffles how the top edge was deformed from getting the socket wrench in and out.

All the cylinders cool well in cruise and climb with the new baffles (actually, I didn't have any cooling problems with the old ones either, but they were old and tired, and needed to be replaced).

Thanks,

Michael

Michael W. Meyer

Tiger N74086

San Francisco, CA

michael(at)flightsked.com (michael(at)flightsked.com)

On Jul 7, 2011, at 12:23 PM, Gary Vogt wrote:

[quote]I did my Citabria, which has baffles that are not that different from those on a Bonanza, using my technique. I used 1/4 as much hardware and accomplished the same thing. The Citabria had baffle seals mounted on the inside. I copied them. By the time I was done, I wished I'd done them differently. Still, it worked OK.

I've included a few pics.

• The first one is a customer I did a few years ago. This is how the baffle lays over without any help.

•The next several pics are of an installation where the metal baffle was deformed to make the baffles fit. It's a brute force method that is really ugly and makes maintenance difficult.

•The next two are of my Citabria.

•The last one is of an installation of a LoPresti nosebowl. Notice the gap in the corner. There is no way to elegantly fill this gap. Unless the installer knows what he's doing, CHTs will be higher after installing a LoPresti nosebowl.

From: flyv35b <flyv35b(at)minetfiber.com (flyv35b(at)minetfiber.com)>

To: teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

Sent: Thu, July 7, 2011 8:47:35 AM

Subject: Re: why put baffle seals outside the baffle

I believe that a good installation can be done either way. I've seen

baffles that were installed incorrectly from the back side that were cut

by the sharp edge of the metal baffle, probably because there wasn't

enough clearance between it and the cowling.

Here are 3 photos of what is a totally different arrangement than what

has been discussed, albeit not on a Grumman. Note that in the photo

(P1060256) of the front side that a top metal strip is riveted to a

flange and it sandwiches the seal material, forcing it to bend forward

and form a nice curvature.

The last photo (P106057) shows the oil cooler installation on the

opposite, LH side where the cooler is set back about 1.5 inches behind

the cylinder fins for improved air entrance flow. I think the Tiger

cooler could benefit from this sort of thing, although it wouldn't need

to be set back nearly as far.

Cliff

On 7/6/2011 8:33 PM, Gary Vogt wrote:

| Quote: | Barry,

I would challenge any installation you could do with what I do regarding

longevity, sealing ability, and looks compared to mine. Inside is just

not right.

------------------------------------------------------------------------

*From:* FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)>

*To:* teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

*Sent:* Wed, July 6, 2011 6:44:29 PM

*Subject:* Re: why put baffle seals outside the baffle

Boris, Gary & Team:

Here are my thoughts on In Vs Out:

1. There is no advantage of putting the silicon baffle material on

the outside. Only a disadvantage.

* Why? Well if you think about it there is only 0.025 to

0.035" difference in position between inside and out. The

thickness of the metal baffle.

* The difference is in which direction the NATURAL ROLL of the

silicon goes. YOU MUST place the curve of the silicon baffle

material to the INSIDE. This is true for BOTH the LENGTH and

the WIDTH of the silicon baffle material.

* THERE IS A CURVE! ! !

* It's ugly! But beauty is in the eye of the beholder.

2. Reinforced Vs Un-Reinforced:

* The Un-Reinforced is softer and will bend easier and conform

easier.

* The Un-Reinforced will also deform easier when the

Pop-Rivets are squeezed down. This causes and adds to the

scalloping of the silicon baffle material.

* The Un-Reinforced will tear easier.

3. The Cure for problems in #2 above:

* I use 1/8" thick x 1/2" wide x Required LONG LENGTHS of

aluminum strips that function as a CONTINUOUS WASHER to hold

down the silicon baffle material against the aluminum baffle

material.

* This FLATTENS the silicon baffle material ELIMINATING ALL

scalloping as well as stiffening the aluminium baffle material.

* So NOW you can use the softer, more flexible Non-Reinforced

silicon baffle material. Which will give you a better seal

and less ware.

* So, why on the inside if you do all the above? It LQQKs a

hell of a lot better.

* Yes, you can still use the LONG LENGTHS of aluminum strips

that function as a CONTINUOUS WASHER to hold down the

silicon baffle material against the aluminum baffle material

- On The Out Side.

* Oh! I use 5/8" Dia HEAD x 1/8" Dia Shank x 1/2" Long Shank -

Pop-Rivets.

* To prevent tearing I stitch the over laps in the corners and

'V' cuts with dental floss.

Barry

On Wed, Jul 6, 2011 at 12:43 PM, b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)

<mailto:bvnj(at)yahoo.com (bvnj(at)yahoo.com)>> wrote:

--> TeamGrumman-List message posted by: b v <bvnj(at)yahoo.com (bvnj(at)yahoo.com)

<mailto:bvnj(at)yahoo.com (bvnj(at)yahoo.com)>>

Gary and all,

A number of people suggest that if you put seals on the inside, the

air pressure pushes them against the baffles and provides a better

seal, while if you put them outside, the air will try to escape

between the rivets.

So what are the reasons to put the baffle seals on the outside of

the cylinder and rear baffles?

Thank you,

-Boris

===========

List"

target="_blank">http://www.matronics.com/Navigator?TeamGrumman-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

*

*

*

*

|

<Baffles_18.jpg><BafflesNot_01.jpg><BafflesNot_02.jpg><BafflesNot_03.jpg><BafflesNot_04.jpg><BafflesNot_05.jpg><BafflesNot_06.jpg><BafflesNot_07.jpg><CitabriaEngine_Lt.jpg><CitabriaEngine_Rt.jpg><10-2003 050.jpg>

[b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|