|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

tonyvaccarella

Joined: 10 Sep 2014

Posts: 68

Location: Australia

|

|

| Back to top |

|

|

wdaniell.longport(at)gmai

Guest

|

Posted: Fri Jul 08, 2016 5:35 am Post subject: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 5:35 am Post subject: Curing of Flying Surfaces |

|

|

Tony

I was originally daunted by this but it's actually easy. I bought some 1mx1m expanded polystyrene and built box/oven 1 x 1 x 2. this was enough for my foam flying surfaces flaps, horizontal stab, ailerons.

I used ordinary fan heaters inside the oven and removed the standard thermostat and replaced it with a thermostat from Aircraft spruce calibrated to 40C i think.

I but a baffle in front of the of the fan to ensure that there was no local concentration of heat.

I used a couple of meat thermomenters punched through the polystyrene to monitor the temperature.

Once i worked it out it was a couple of hours to do the job.

Will

William Daniell

LONGPORT

+57 310 295 0744

On Fri, Jul 8, 2016 at 5:08 AM, tonyvaccarella <tony(at)weimagine.com.au (tony(at)weimagine.com.au)> wrote:

| Quote: | --> Europa-List message posted by: "tonyvaccarella" <tony(at)weimagine.com.au (tony(at)weimagine.com.au)>

Hello all,

I'm the owner of a conventional tailwheel aircraft I purchased from the USA. This project was started in 1999 and still being built

Not that Im near the finished stage yet but while reading the Builders Manual about finishing the aircraft it states

" The first thing that you need to do with your flying surfaces is port cure them at a temperature between 40-50 deg C. This will improve their strength and cook off any remaining volatiles and moisture withing the epoxy system. "

Just wondering how builders have managed to do this. What equipment that have used and how they have controlled the temperature. What is our opinion about doing this on "old" wings that were completed in about year 2000.

I look forward to your comments

Regards,

Tony Vaccarella

Sydney

Australia

--------

Tony Vaccarella

Mascot NSW 2020

Sydney Australia

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=457901#457901

===========

pa-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Europa-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

pete(at)lawless.info

Guest

|

Posted: Fri Jul 08, 2016 6:05 am Post subject: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 6:05 am Post subject: Curing of Flying Surfaces |

|

|

Hi Tony

I used the exact same method as William. We happened to have a couple of domestic extractor fans left over from a job and I added those in the oven to make sure the air got well swirled about and there were no local hot spots.

Regards

Pete

G-RMAC Classic #109

On 08/07/16 14:33, William Daniell wrote:

| Quote: | Tony

I was originally daunted by this but it's actually easy. I bought some 1mx1m expanded polystyrene and built box/oven 1 x 1 x 2. this was enough for my foam flying surfaces flaps, horizontal stab, ailerons.

I used ordinary fan heaters inside the oven and removed the standard thermostat and replaced it with a thermostat from Aircraft spruce calibrated to 40C i think.

I but a baffle in front of the of the fan to ensure that there was no local concentration of heat.

I used a couple of meat thermomenters punched through the polystyrene to monitor the temperature.

Once i worked it out it was a couple of hours to do the job.

Will

William Daniell

LONGPORT

+57 310 295 0744

On Fri, Jul 8, 2016 at 5:08 AM, tonyvaccarella <tony(at)weimagine.com.au (tony(at)weimagine.com.au)> wrote:

| Quote: | --> Europa-List message posted by: "tonyvaccarella" <[url=mailto:tony(at)weimagine.com.au]tony(at)weimagine.com.au (tony(at)weimagine.com.au)[/url]>

Hello all,

I'm the owner of a conventional tailwheel aircraft I purchased from the USA. This project was started in 1999 and still being built

Not that Im near the finished stage yet but while reading the Builders Manual about finishing the aircraft it states

" The first thing that you need to do with your flying surfaces is port cure them at a temperature between 40-50 deg C. This will improve their strength and cook off any remaining volatiles and moisture withing the epoxy system. "

Just wondering how builders have managed to do this. What equipment that have used and how they have controlled the temperature. What is our opinion about doing this on "old" wings that were completed in about year 2000.

I look forward to your comments

Regards,

Tony Vaccarella

Sydney

Australia

--------

Tony Vaccarella

Mascot NSW 2020

Sydney Australia

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=457901#457901

===========

pa-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Europa-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

tonyvaccarella

Joined: 10 Sep 2014

Posts: 68

Location: Australia

|

Posted: Fri Jul 08, 2016 6:45 am Post subject: Re: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 6:45 am Post subject: Re: Curing of Flying Surfaces |

|

|

Thanks for the reply.

My problem is (my challenge is) that I have the old classic wing and need to put the entire wing in the hot box. Despite the size, do you consider the principle the same?

Many thanks once again.

Regards,

Tony

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Tony Vaccarella

Mascot NSW 2020

Sydney Australia |

|

| Back to top |

|

|

wdaniell.longport(at)gmai

Guest

|

Posted: Fri Jul 08, 2016 7:15 am Post subject: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 7:15 am Post subject: Curing of Flying Surfaces |

|

|

When I ask the question a while back some guys who lived in hot countries mentioned that they had built a tent out of black plastic if that helps

William Daniell

LONGPORT

+57 310 295 0744

On Fri, Jul 8, 2016 at 9:45 AM, tonyvaccarella <tony(at)weimagine.com.au (tony(at)weimagine.com.au)> wrote:

| Quote: | --> Europa-List message posted by: "tonyvaccarella" <tony(at)weimagine.com.au (tony(at)weimagine.com.au)>

Thanks for the reply.

My problem is (my challenge is) that I have the old classic wing and need to put the entire wing in the hot box. Despite the size, do you consider the principle the same?

Many thanks once again.

Regards,

Tony

--------

Tony Vaccarella

Mascot NSW 2020

Sydney Australia

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=457918#457918

===========

pa-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Europa-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

ptag.dev(at)talktalk.net

Guest

|

Posted: Fri Jul 08, 2016 7:47 am Post subject: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 7:47 am Post subject: Curing of Flying Surfaces |

|

|

Hi! Will and Tony,

Concerning curing of the Europa.

I notice that it is being suggested that a cure time of possibly two hours was likely.

May I respectfully advise that if you have an aircraft that is glass fibre reinforced with resins laid over polystyrene you need to very slowly increase the heat soak or you will have the polystyrene expand faster than the glass and burst through the construction making you a very unhappy bunny ! Likewise the cooling down cycle needs similar treatment.

Regards

Bob Harrison G-PTAG .

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of William Daniell

Sent: 08 July 2016 14:34

To: europa-list(at)matronics.com

Subject: Re: Curing of Flying Surfaces

Tony

I was originally daunted by this but it's actually easy. I bought some 1mx1m expanded polystyrene and built box/oven 1 x 1 x 2. this was enough for my foam flying surfaces flaps, horizontal stab, ailerons.

I used ordinary fan heaters inside the oven and removed the standard thermostat and replaced it with a thermostat from Aircraft spruce calibrated to 40C i think.

I but a baffle in front of the of the fan to ensure that there was no local concentration of heat.

I used a couple of meat thermomenters punched through the polystyrene to monitor the temperature.

Once i worked it out it was a couple of hours to do the job.

Will

William Daniell

LONGPORT

+57 310 295 0744

On Fri, Jul 8, 2016 at 5:08 AM, tonyvaccarella <tony(at)weimagine.com.au (tony(at)weimagine.com.au)> wrote:

--> Europa-List message posted by: "tonyvaccarella" <tony(at)weimagine.com.au (tony(at)weimagine.com.au)>

Hello all,

I'm the owner of a conventional tailwheel aircraft I purchased from the USA. This project was started in 1999 and still being built

Not that Im near the finished stage yet but while reading the Builders Manual about finishing the aircraft it states

" The first thing that you need to do with your flying surfaces is port cure them at a temperature between 40-50 deg C. This will improve their strength and cook off any remaining volatiles and moisture withing the epoxy system. "

Just wondering how builders have managed to do this. What equipment that have used and how they have controlled the temperature. What is our opinion about doing this on "old" wings that were completed in about year 2000.

I look forward to your comments

Regards,

Tony Vaccarella

Sydney

Australia

--------

Tony Vaccarella

Mascot NSW 2020

Sydney Australia

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=457901#457901

===========

pa-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Europa-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

tonyvaccarella

Joined: 10 Sep 2014

Posts: 68

Location: Australia

|

Posted: Fri Jul 08, 2016 7:59 am Post subject: Re: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 7:59 am Post subject: Re: Curing of Flying Surfaces |

|

|

Hi William,

That would certainly do it here in Sydney Australia. Thanks for the food for thought.

Regards,

Tony

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Tony Vaccarella

Mascot NSW 2020

Sydney Australia |

|

| Back to top |

|

|

pete(at)lawless.info

Guest

|

Posted: Fri Jul 08, 2016 8:10 am Post subject: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 8:10 am Post subject: Curing of Flying Surfaces |

|

|

Tony my hot box was big enough to take the complete classic wing. I did

three sessions, one for each wing and one for all the other bits.

Pete

PS Can't you just wait for the summer and turn the aircon off in the

workshop?

On 08/07/16 15:45, tonyvaccarella wrote:

| Quote: |

Thanks for the reply.

My problem is (my challenge is) that I have the old classic wing and need to put the entire wing in the hot box. Despite the size, do you consider the principle the same?

Many thanks once again.

Regards,

Tony

--------

Tony Vaccarella

Mascot NSW 2020

Sydney Australia

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=457918#457918

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

wdaniell.longport(at)gmai

Guest

|

Posted: Fri Jul 08, 2016 11:14 am Post subject: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 11:14 am Post subject: Curing of Flying Surfaces |

|

|

Bob

well i didn't know that and all went well so I guess I got lucky either that or the ambient temp here is sufficient.

Tony you can find a pic of my oven in the photos on my website under phots "the Oven"

https://sites.google.com/site/europaconstructionwd/

Will

William Daniell

LONGPORT

+57 310 295 0744

On Fri, Jul 8, 2016 at 10:45 AM, Bob Harrison <ptag.dev(at)talktalk.net (ptag.dev(at)talktalk.net)> wrote:

| Quote: |

Hi! Will and Tony,

Concerning curing of the Europa.

I notice that it is being suggested that a cure time of possibly two hours was likely.

May I respectfully advise that if you have an aircraft that is glass fibre reinforced with resins laid over polystyrene you need to very slowly increase the heat soak or you will have the polystyrene expand faster than the glass and burst through the construction making you a very unhappy bunny ! Likewise the cooling down cycle needs similar treatment.

Regards

Bob Harrison G-PTAG .

From: owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com) [mailto:owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com)] On Behalf Of William Daniell

Sent: 08 July 2016 14:34

To: europa-list(at)matronics.com (europa-list(at)matronics.com)

Subject: Re: Curing of Flying Surfaces

Tony

I was originally daunted by this but it's actually easy. I bought some 1mx1m expanded polystyrene and built box/oven 1 x 1 x 2. this was enough for my foam flying surfaces flaps, horizontal stab, ailerons.

I used ordinary fan heaters inside the oven and removed the standard thermostat and replaced it with a thermostat from Aircraft spruce calibrated to 40C i think.

I but a baffle in front of the of the fan to ensure that there was no local concentration of heat.

I used a couple of meat thermomenters punched through the polystyrene to monitor the temperature.

Once i worked it out it was a couple of hours to do the job.

Will

William Daniell

LONGPORT

+57 310 295 0744

On Fri, Jul 8, 2016 at 5:08 AM, tonyvaccarella <tony(at)weimagine.com.au (tony(at)weimagine.com.au)> wrote:

--> Europa-List message posted by: "tonyvaccarella" <tony(at)weimagine.com.au (tony(at)weimagine.com.au)>

Hello all,

I'm the owner of a conventional tailwheel aircraft I purchased from the USA. This project was started in 1999 and still being built

Not that Im near the finished stage yet but while reading the Builders Manual about finishing the aircraft it states

" The first thing that you need to do with your flying surfaces is port cure them at a temperature between 40-50 deg C. This will improve their strength and cook off any remaining volatiles and moisture withing the epoxy system. "

Just wondering how builders have managed to do this. What equipment that have used and how they have controlled the temperature. What is our opinion about doing this on "old" wings that were completed in about year 2000.

I look forward to your comments

Regards,

Tony Vaccarella

Sydney

Australia

--------

Tony Vaccarella

Mascot NSW 2020

Sydney Australia

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=457901#457901

===========

pa-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?Europa-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

spcialeffects

Joined: 29 Aug 2012

Posts: 306

Location: Kent

|

Posted: Fri Jul 08, 2016 1:11 pm Post subject: Re: Curing of Flying Surfaces Posted: Fri Jul 08, 2016 1:11 pm Post subject: Re: Curing of Flying Surfaces |

|

|

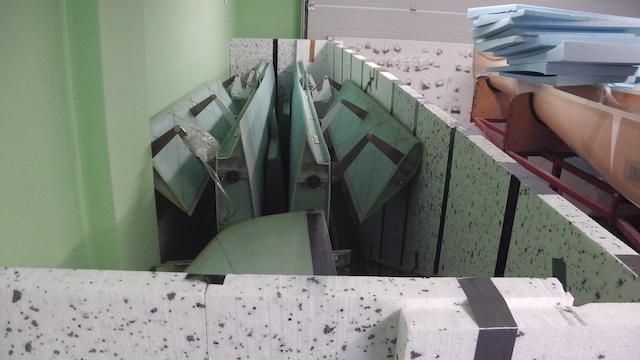

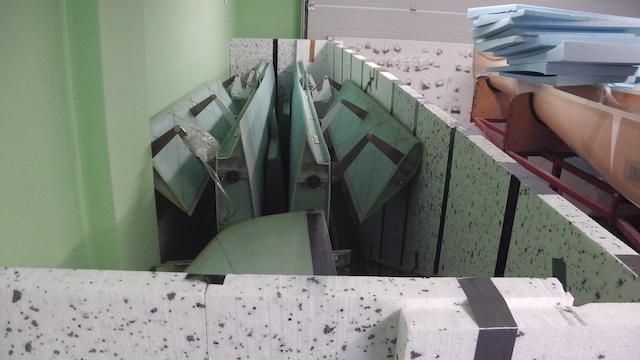

Hi Tony. I did what Bob said and slowly increased the temperature kept it at 50 degrees for about 16 hours then turned off the heaters and left it covered up for about another 10 hours. I too have classic wing and baked everything at once.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

175.85 KB |

| Viewed: |

10861 Time(s) |

|

| Description: |

|

| Filesize: |

172.39 KB |

| Viewed: |

10861 Time(s) |

|

|

|

| Back to top |

|

|

Richard Lamprey

Joined: 15 Jul 2011

Posts: 95

Location: Kenya

|

Posted: Sat Jul 09, 2016 5:42 am Post subject: Re: Curing of Flying Surfaces Posted: Sat Jul 09, 2016 5:42 am Post subject: Re: Curing of Flying Surfaces |

|

|

Hi Tony,

My Classic (no 168), which I built in Kenya, was the first complete kit (Stages 1,2,3,4) sold by Europe, and as such was airfreighted to Kenya in a long 18' wooden box. For the curing, I reconstructed the box, covered the inner surfaces with thin expanded foam, put in the wings (later fuselage), and left it out in the Kenya sun for 5 days and nights. Temp outside daytime was 28 C, 18 C night-time, inside the box during day up to 43 C. Cured fine. Best, Richard

Classic Kenya, monowheel, 912 ULS, reg 5Y-LRY, 650 hours

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rlborger(at)mac.com

Guest

|

Posted: Sun Jul 10, 2016 8:40 am Post subject: Curing of Flying Surfaces Posted: Sun Jul 10, 2016 8:40 am Post subject: Curing of Flying Surfaces |

|

|

Tony,

Been away on a short vacation via my Europa. You need to finish to enjoy the flying!

Anyway, go to http://www.europaowners.org/main.php?g2_itemId=60876 to see what I did to cure my surfaces. I used two fairly small electric space heaters, one placed low on one end and one placed high on the other. I used an electronic thermometer with two inputs so I could monitor the heat in two locations to confirm proper thermal environment. Darn thing worked great.

Just another idea for you.

Blue skies & tailwinds,

Bob Borger

Europa XS Tri, Rotax 914, Airmaster C/S Prop (75 hrs).

Little Toot Sport Biplane, Lycoming Thunderbolt AEIO-320 EXP

3705 Lynchburg Dr.

Corinth, TX 76208-5331

Cel: 817-992-1117

rlborger(at)mac.com

On Jul 8, 2016, at 5:08 AM, tonyvaccarella <tony(at)weimagine.com.au> wrote:

Hello all,

I'm the owner of a conventional tailwheel aircraft I purchased from the USA. This project was started in 1999 and still being built

Not that Im near the finished stage yet but while reading the Builders Manual about finishing the aircraft it states

" The first thing that you need to do with your flying surfaces is port cure them at a temperature between 40-50 deg C. This will improve their strength and cook off any remaining volatiles and moisture withing the epoxy system. "

Just wondering how builders have managed to do this. What equipment that have used and how they have controlled the temperature. What is our opinion about doing this on "old" wings that were completed in about year 2000.

I look forward to your comments

Regards,

Tony Vaccarella

Sydney

Australia

--------

Tony Vaccarella

Mascot NSW 2020

Sydney Australia

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|